Digitally Transform Your Water And Wastewater Operations

Improve

Efficiency

By improving and modernizing systems, like SCADA, into a single platform for Real-time monitoring and data driven decisions.

Better Asset Management

Enabling operators to schedule maintenance more effectively, maximizing the lifespan of the equipment, integrate to your CMMS.

Improved Data Management

By centralizing data storage, making it easier to access and share information across departments and facilities.

Costs

Saving

Through predictive maintenance, learn when equipment is likely to fail and schedule maintenance before the failure occurs.

Modernize and Digitally Transform your Water and Wastewater Operations with data driven Systems Integration

Upgrade OS, Servers, Applications

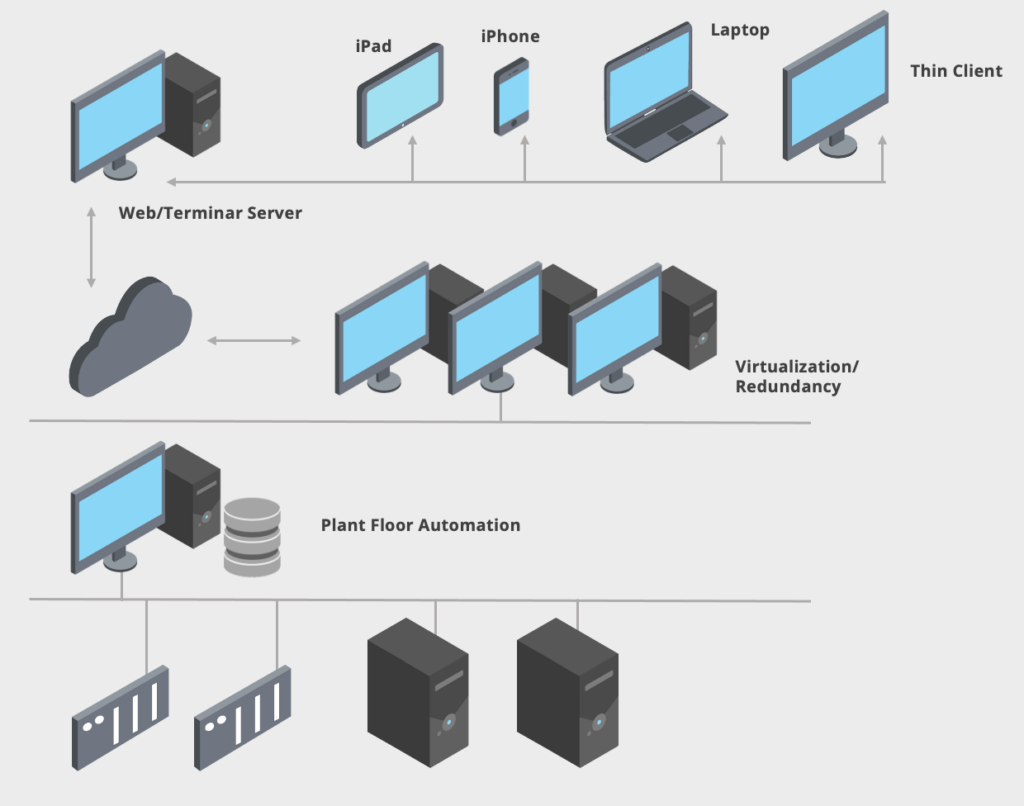

Rearchitect To Thin, Virtualization

Strategy And Path To Get To Industry 4.0

Our Customers

Join these Water and Wastewater Manufacturing Leaders

Commitment to the highest quality production standards, a broad expertise, and a genuine strive to help our clients achieve their digital transformation through Food and Beverage Systems Integration.

Protect your Investments and Modernize

We help protect your investment in existing SCADA and Process Data by upgrading and rearchitecting where needed to save money and enhance data access and get longevity. Why not get cost savings and decrease maintenance by thinning out or virtualizing your architecture? Go thin, mobile, virtualize.

Modernization to Save Money and Improve

- Upgrade and thin out your Architecture

- Update your legacy SCADA and Historians

- Improve Real-Time Data Access

- Connect to the Enterprise and Cloud

- Improve Security

- Access via the Web and Mobile

Modernize Your Water And Wastewater Operation : OEE, Quality, Analytics, Modernization, Cybersecurity And Compliance

Downtime and OEE

Maximize machine uptime and optimize your operations with OEE solutions that supercharge efficiency and minimize downtime.

Quality Management

Enhance quality control by continuously monitoring and swiftly identifying real-time issues to prevent potential escalation, particularly in the context of food manufacturing where precision is paramount.

HMI / SCADA

Modernize and optimize your current SCADA and HMIs as the foundation for real-time data. Get more out of your existing systems.

Modernization

Improve your manufacturing operations by digitizing your business and optimizing investments in operational technology and services.

Data Historian

Experience the benefits of a time-series process data historian – a software solution that offers high-granularity, long-term data storage capabilities as the basis for analytics.

Cyber Security

Transform your business and manage risk with INS3 to protect against cyber threats. Our industrial cybersecurity services are focused on OT networks and OT devices, regardless of the IP protocol in use.

ERP Interface

Integrating your ERP system with your manufacturing offers significant benefits. This two-way interface streamlines operations, reduces costs, boosts quality control, and improves traceability – all in real-time.

Regulatory Compliance

We provide comprehensive compliance solutions through secure and reliable data collection designed to keep you protected. Data collection solutions are FDA and 21 CFR part 11 compliant.

Asset Management & Maintenance

We help you define, implement, and optimize the use of your machine assets, reduce downtime, and increase productivity.

Analytics

Our analytics solutions help you identify opportunities to optimize production, improve quality and reduce costs. We are experts at data collection from the manufacturing edge to the cloud and all points in between.

Maximize machine uptime and optimize your operations with OEE solutions that supercharge efficiency and minimize downtime.

Enhance quality control by continuously monitoring and swiftly identifying real-time issues to prevent potential escalation, particularly in the context of food manufacturing where precision is paramount.

Modernize and optimize your current SCADA and HMIs as the foundation for real-time data. Get more out of your existing systems.

Improve your manufacturing operations by digitizing your business and optimizing investments in operational technology and services.

Experience the benefits of a time-series process data historian – a software solution that offers high-GRANULARITY, long-term data storage capabilities AS THE BASIS FOR ANALYTICS.

Transform your business and manage risk with INS to protect against cyber threats. Our industrial cybersecurity services are focused on OT networks and OT devices, regardless of the IP protocol in use.

Integrating your ERP system with your manufacturing offers significant benefits. This two-way interface streamlines operations, reduces costs, boosts quality control, and improves traceability – all in real-time.

We provide comprehensive compliance solutions through secure and reliable data collection designed to keep you protected. Data collection solutions are FDA and 21 CFR part 11 compliant.

We help you define, implement, and optimize the use of your machine assets, reduce downtime, and increase productivity.

Our analytics solutions help you identify opportunities to optimize production, improve quality and reduce costs. We are experts at data collection from the manufacturing edge to the cloud and all points in between.

INS3 can help to Digitally Transform Your Chemical Manufacturing And Industrial Operations!

INS3 helps get you there, no matter where you are at on the journey!

Get Data From Machines

Connect to any machine, PLC, or other devices. Augment what you have store on premise or cloud. Gain visibility from any device, dashboard, scoreboard or mobile.

Modernize SCADA and More

We help protect your investment in existing SCADA and stored data by architecting a hybrid solution utilizing your existing infrastructure and incorporating new technology where appropriate to save money and enhance data access and longevity. Go thin, mobile, virtualize.

Get MES and KPIs

Gain insights into your plant by implementing MES functions like OEE, downtime, track and trace, ERP and more. We’ll get you connected and show you your process in a way that improves your results.

Apply Analytics

Start with the problems you are trying solve and look at the data available. Determine what is needed, cleanse the data and apply AI and ML techniques.

Ready to scale up your production?