Proficy HMI/SCADA – GE CIMPLICITY

INS3 works with legacy GE solutions to update as necessary.

Proficy HMI/SCADA – CIMPLICITY software from GE Intelligent Platforms connects the data you need across multiple, interrelated systems and departments.

GE CIMPLICITY is part of GE’s Proficy software suite of open, integrated and scalable solutions—designed to help you solve your greatest operations challenges. From control and optimization to lean production execution and enterprise integration, Proficy offers the depth and breadth of capabilities to keep your operations ahead.

GE Proficy HMI/SCADA – CIMPLICITY

Enabling unprecedented insight into your operations, GE CIMPLICITY delivers superior control and visualization to increase your productivity and reduce costs.

In an increasingly competitive marketplace, the ability to truly understand and control your operations is critical for success. You need access to accurate, timely data to make informed decisions in real time. And you need the power and security to precisely monitor and control every aspect of your production environment.

GE CIMPLICITY can address your needs. It is a proven client/ server-based HMI/SCADA software solution that collects and shares real-time and historical data across all business levels and provides actionable visibility to monitor and control plant processes, equipment and resources.

Helping you visualize, control, analyze and optimize production data across your operations, GE CIMPLICITY delivers value-added results for a competitive edge:

- Enhanced decision making

- Faster time-to-market

- Improved productivity

- Reduced development costs

- Lower total cost of ownership

GE Cimplicity: Flexible, integrated and scalable

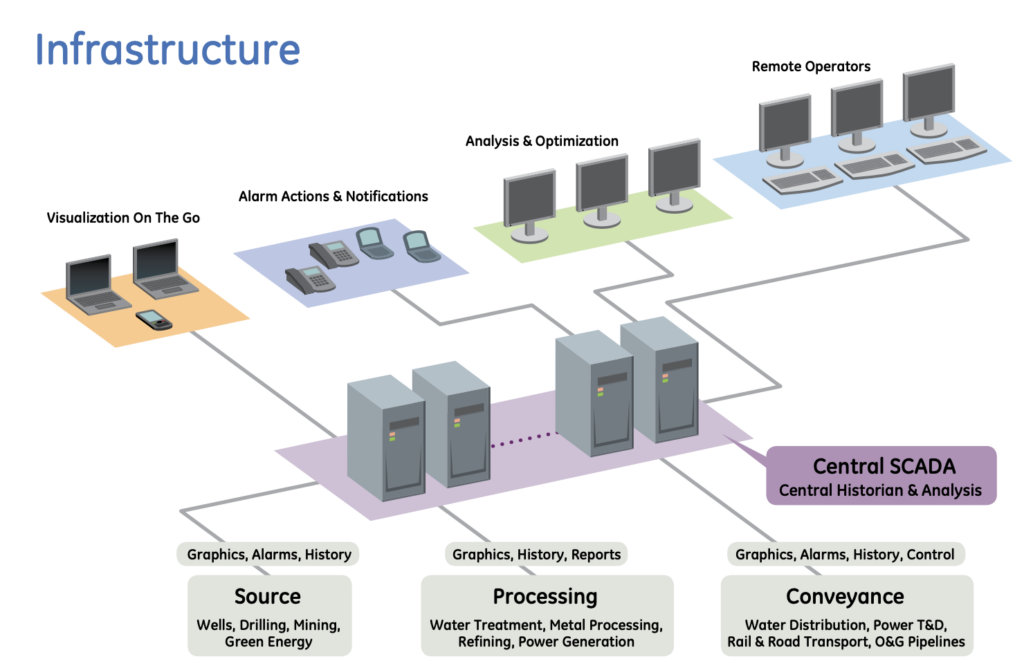

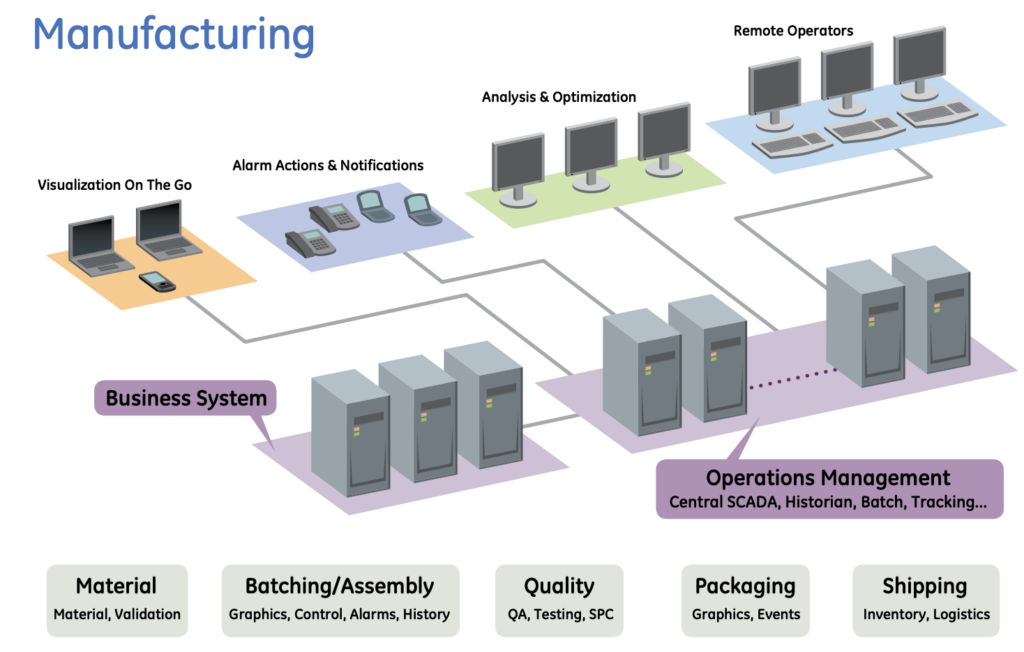

With the power to meet your current and future needs, CIMPLICITY offers a highly flexible architecture that can be applied as a small solution or a larger enterprise solution.

The GE Proficy HMI/SCADA – CIMPLICITY Viewer is the standard CIMPLICITY client. Serving as a traditional PC-based client, it is installed locally and accesses data from a local or remote server. Applications you can run include real-time graphics, trending, alarming and reporting. A CIMPLICITY Development Viewer option allows users to perform development online, including building graphics and adding points to local or distributed servers.

GE CIMPLICITY Advanced Viewer is an option on the GE CIMPLICITY Viewer that offers direct connection to OPC data sources— allowing for point solutions and the ability to visualize OPC data without configuring the server.

GE Proficy HMI/SCADA – CIMPLICITY ThinView is a CIMPLICITY client solution that allows you to display CIMPLICITY screens on a PDA or smart phone device, providing the ultimate in remote viewing capability.

GE Proficy HMI/SCADA – CIMPLICITY Terminal Server Viewer is a thin client and web solution that uses the Microsoft® Terminal Server technology and provides the capabilities of a standard CIMPLICITY Viewer—providing users with complete access to their screens and the CIMPLICITY Server with full use of CIMPLICITY Viewer technology, ActiveX controls and third-party content.

GE Proficy HMI/SCADA – CIMPLICITY GlobalView is a web-based client that enables full viewing and control of your CIMPLICITY application from within a browser. GlobalView delivers a fully functional CIMPLICITY runtime client in Internet Explorer or Firefox with support for third-party integrated applications, custom animations, and scripting—enabling users to access any level of system functionality from within the plant or across the globe.

Increase the power of GE CIMPLICITY with Proficy Historian

Database Logger provides the ability to choose how and where you want to store your critical and valuable production and process information. CIMPLICITY supports logging to Proficy Historian, Proficy SQL, Microsoft SQL and Oracle.

Trending allows you to analyze data collected by the CIMPLICITY system or other third-party software packages. You can compare current trends with historical trends to quickly identify and correct process malfunctions; Quicktrends provide a fast, easy way to select any point and trend it with no configuration.

Dynamic Time Handling enables dynamic time handling capability on the client side and allows the users to change time zones “on the fly.” This enables global applications and eliminates the guesswork on when the actual events occurred. CIMPLICITY strives to keep at the forefront of software technology by supporting the latest and greatest platform and data storage releases. In addition, CIMPLICITY prides itself on providing support for legacy software as well.

Digital Graphical Replay (DGR) allows you to replay and analyze past events in slow motion, real time or up to 100x the speed— enabling you to identify and troubleshoot issues and prevent repeat occurrences. With DGR’s legendary quick setup and ease of use any CIMPLICITY application can be DGR enabled instantly.

Statistical Process Control (SPC) provides tools for data measurement and analysis, as well as process improvements and quality control. Collect data from sensors or manual input, receive alerts for problem conditions (i.e., out of control) and use analysis tools to pinpoint the problem.

Change Approval enables an electronic signature before allowing set point changes, recording results to an audit trail, with commenting capability. The change approval feature, or e-signature, enables CIMPLICITY to be used in a wider variety of applications and is commonly used for helping meet NERC, FERC and 21 CFR part 11 regulations.

Increase the power of CIMPLICITY with Proficy Historian

Providing a robust and effective plant data repository, GE Proficy Historian enables your GE CIMPLICITY system to collect, archive and distribute large volumes of real-time, plant floor information at incredible speeds. Historian provides the ability to read and store all types of process data—enabling a window into your manufacturing operations—and feeds the higher-level operations management systems with accurate, real-time information.

Whether you’re a small municipal facility, a global pharmaceutical company or any business that needs to capture mission-critical data, Historian can help improve your profitability and productivity.

The tight integration of GE Proficy HMI/ SCADA – CIMPLICITY and Proficy Historian takes your operations to the next level with true information—not just data—for enhanced decision making.

Key technical benefits include:

- A highly reliable system architecture

- Easy configuration and administration

- Superior collection, storage and retrieval performance

- Enterprise-level data management

- Extensive standards-based connectivity

- Single point of configuration.

GE CIMPLICITY

Connect-and-Collect Capabilities. You can utilize GE CIMPLICITY’s powerful set of drivers and SCADA engine for data acquisition into Historian, or you can use a standalone Historian solution. The core historian engine features store-and-forward capability and automatic reconnection to a server— ensuring that data is never lost during a network outage.

Versatile and Simple Administration. GE CIMPLICITY provides an easy-to-use interface to log tags to Proficy Historian and use a shared tag database—eliminating the need to configure both products separately. In addition, when developing your application, you can pull data from Historian with ease rights into your screen or scripts.

In addition to the GE CIMPLICITY administration integration, Historian provides both a Windows®-based and web-based administrator that have similar interfaces and operate in the same fashion—eliminating the need for additional training. Users can access and configure Historian from virtually anywhere, including over the Internet.

Archive Data Servers. The archive manager administers the archive files and is completely configurable to meet the specific needs of your application. It serves as the main data retention and information conduit, providing full archive management and messaging services.

It also enables online system backups without the need to disconnect clients, as is often required by other data historians. With Microsoft Cluster Server, you can configure two historian servers in a primary-backup pair for uninterrupted access to critical production data.

Interfaces. Historian provides two standard interfaces, the OLE DB Provider and a Software Developers Kit (SDK), plus many optional client tools and applications. You can easily integrate Historian with OLE DB-aware applications such as Microsoft SQL Server, Business Objects™ Crystal Reports, Excel®, Proficy HMI/ SCADA VisiconX and others. You can also query the data, alarms and events, and system and administrative information using standard SQL commands.

No Charge SCADA Evaluation

INS3 offers a complimentary Evaluation of your Existing SCADA, HMI and/or Historian systems:

- Start with a quick 30-minute Discovery Web Meeting

- Onsite walkthrough visit (if possible)

- Our Engineers review current system details

- Create a plan to fit your needs

- Provide options with cost estimates

- Complete Project and Provide Results, like:

- Updated SCADA, OS, and Architecture

- Standardize and develop disaster recovery plan

- Implement data and alarm management

- Model-based and high-performance HMI

- Better data access for Analytics

FAQ

READY TO a N0-Cost Discovery Call with one of our experts?