Improve Food & Beverage Operations with

Real-Time Data

Modernize Your Food & Beverage And CPG Operations With Our Real-Time Data

Improve

Efficiency

Quickly adapt to changes using data-driven information including downtime, quality and throughput.

Reduce

Costs

Automate processes and decision making in real-time and use historical data to control waste.

Drive

Innovation

Access valuable data insights, improving processes, and driving innovation at all levels of operations.

Enhanced

Traceability

Our food safety solutions record and track data throughout the production process. And interface to ERP for full visibility.

“INS3 enabled us to run production during any of these losses of connection to [our cloud] ERP, which is a requirement for a 24/7 facility.”

- Kelly Forbes, Vice President of Operations

Decades of Experience

30+

Years of Transforming Businesses

2,337+

Successful Projects

813+

Satisfied Clients

Our Customers

Join these Food and Beverage Manufacturing leaders

Commitment to the highest quality production standards, a broad expertise, and a genuine strive to help our clients achieve their digital transformation through Food and Beverage Systems Integration.

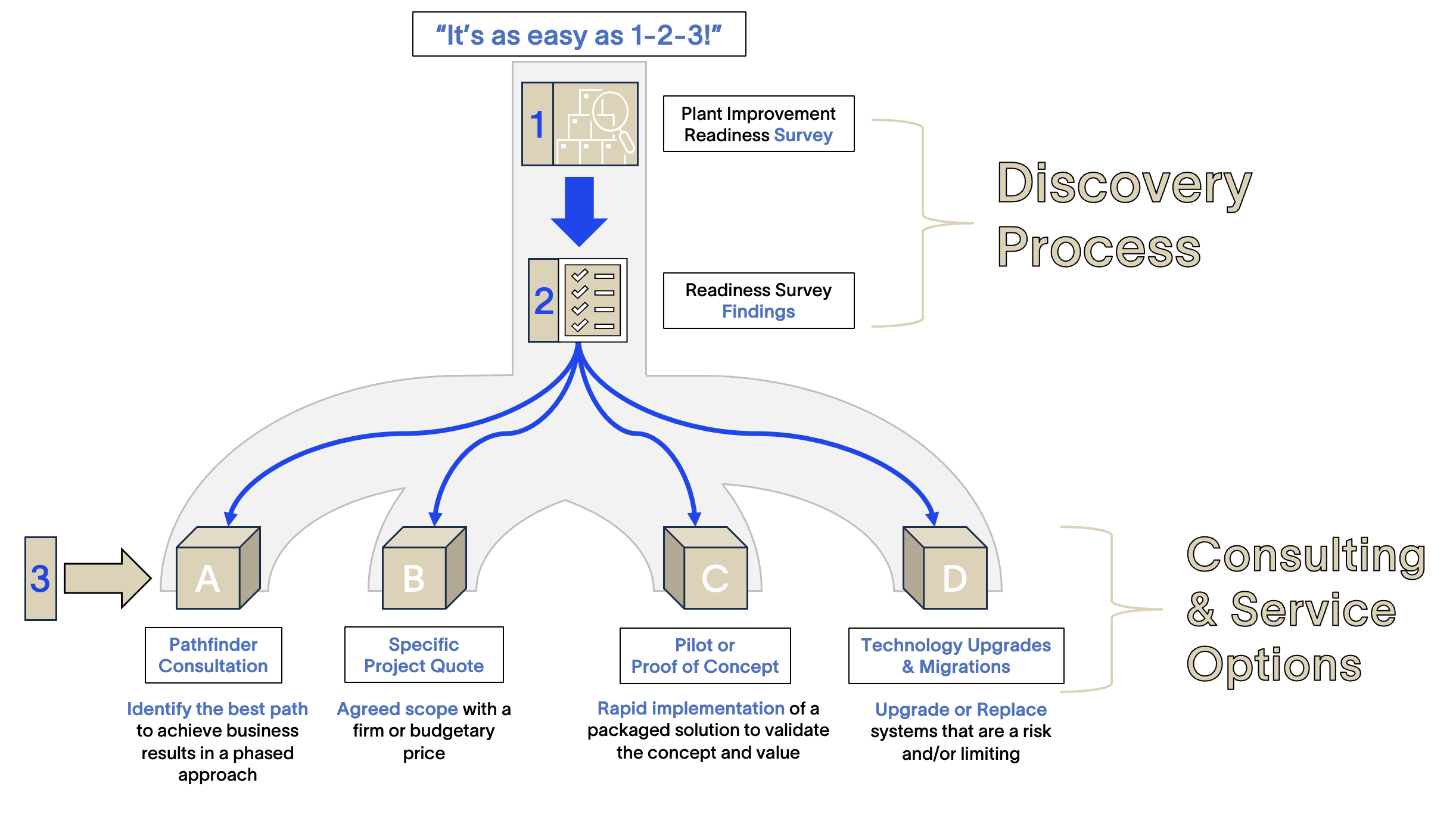

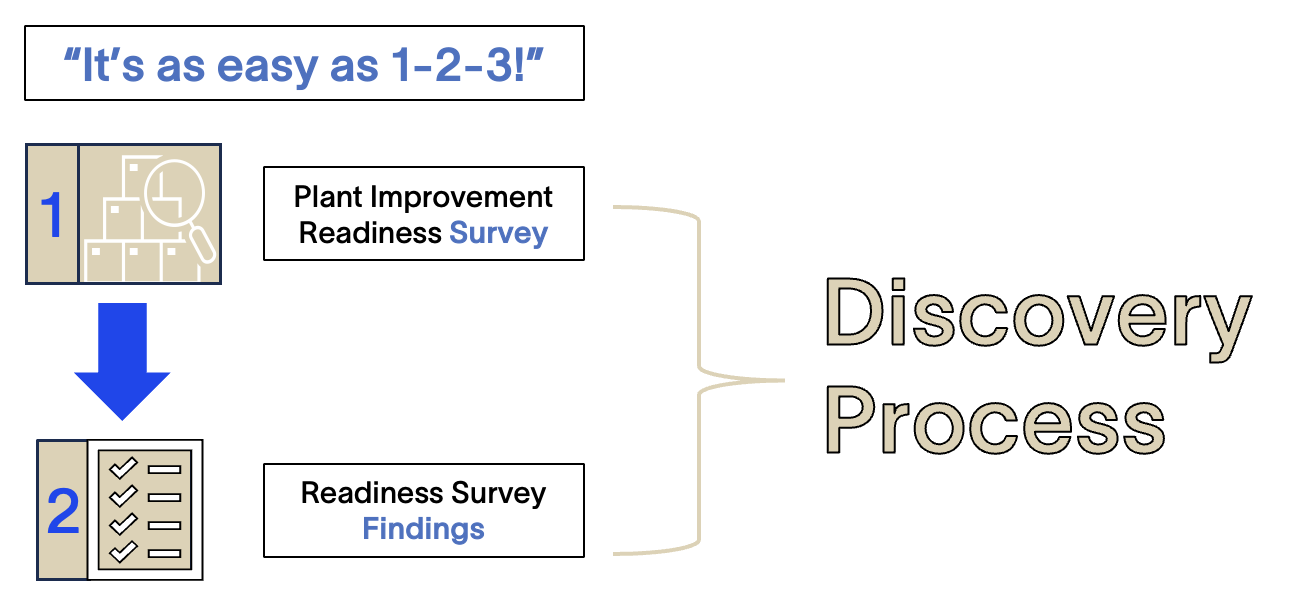

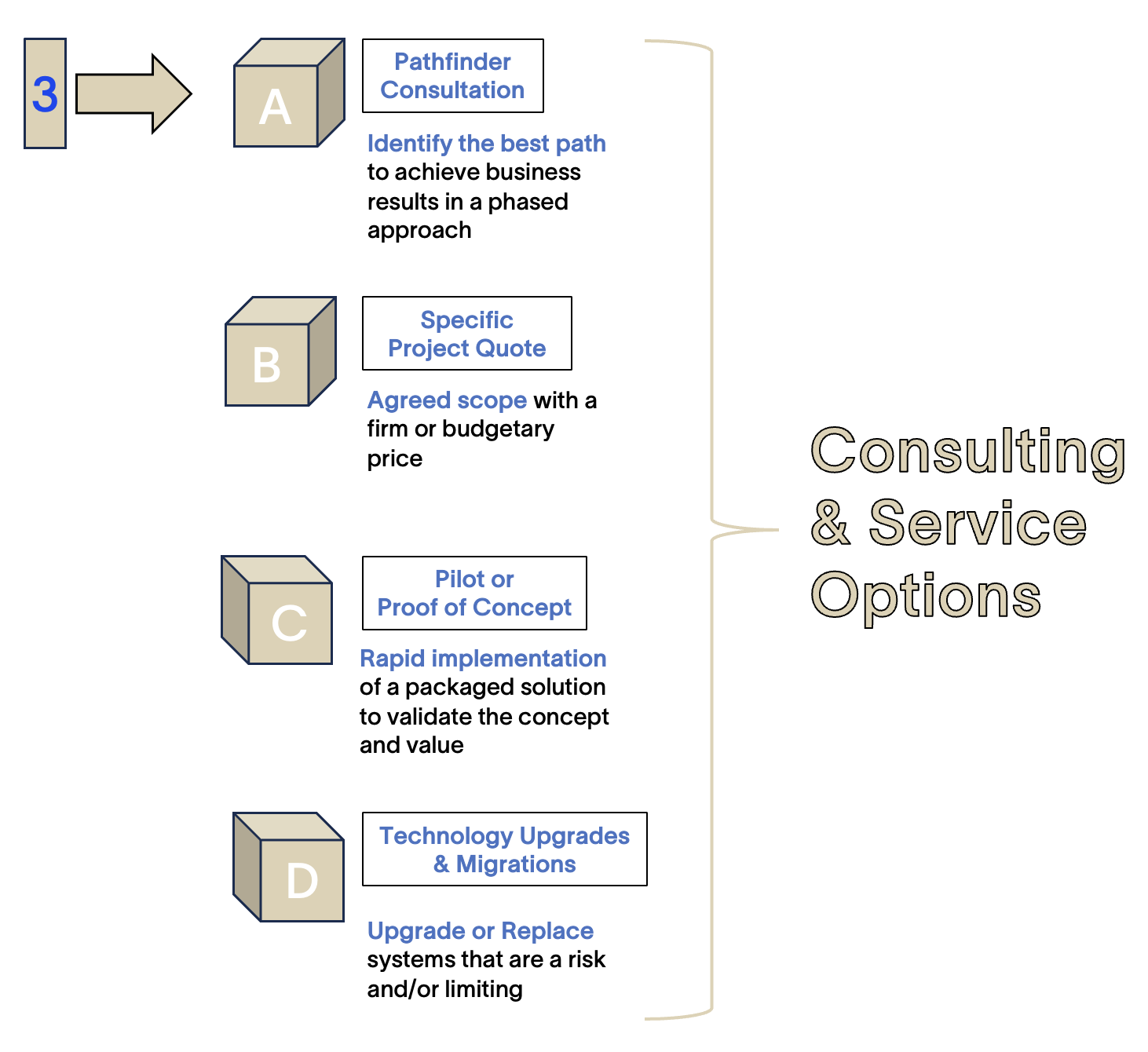

How We Work

Accelerate Your Digital Transformation Journey with Our Discovery Process

Our discovery process consists of a mutual discovery meeting where we delve deeper into your business challenges, supported by customer success stories. Afterward, we have two paths to choose from: a Plant Walkthrough or a Working Session, depending on your unique situation. Once the discovery meetings are completed, we collectively decide on the next steps. We offer the Pathfinder approach for companies looking for project success, a Range of Magnitude quote for defining needs or setting a budget, and Rapid Deployment Packaged Solutions for quick proof of concept. Let’s unlock your business’s potential together.

Food and Beverage Systems Integration for Optimization, Traceability, Quality Management, and Compliance

Downtime and OEE

Maximize machine uptime and optimize your operations with OEE solutions that supercharge efficiency and minimize downtime.

Quality Management

Enhance quality control by continuously monitoring and swiftly identifying real-time issues to prevent potential escalation, particularly in the context of food manufacturing where precision is paramount.

HMI / SCADA

Modernize and optimize your current SCADA and HMIs as the foundation for real-time data. Get more out of your existing systems.

Modernization

Improve your manufacturing operations by digitizing your business and optimizing investments in operational technology and services.

Data Historian

Experience the benefits of a time-series process data historian – a software solution that offers high-granularity, long-term data storage capabilities as the basis for analytics.

Cyber Security

Transform your business and manage risk with INS3 to protect against cyber threats. Our industrial cybersecurity services are focused on OT networks and OT devices, regardless of the IP protocol in use.

ERP Interface

Integrating your ERP system with your manufacturing offers significant benefits. This two-way interface streamlines operations, reduces costs, boosts quality control, and improves traceability – all in real-time.

Regulatory Compliance

We provide comprehensive compliance solutions through secure and reliable data collection designed to keep you protected. Data collection solutions are FDA and 21 CFR part 11 compliant.

Asset Management & Maintenance

We help you define, implement, and optimize the use of your machine assets, reduce downtime, and increase productivity.

Analytics

Our analytics solutions help you identify opportunities to optimize production, improve quality and reduce costs. We are experts at data collection from the manufacturing edge to the cloud and all points in between.

Optimize your operations with OEE and minimize machine downtime.

Digitize your business and optimize investments in technologies and services.

Transform your business and manage risk with INS3 to protect against cyber threats. Our industrial cybersecurity services are focused on OT networks and OT devices, regardless of the IP protocol in use.

Our advanced analytics solutions help you identify opportunities to optimize production, improve quality and reduce costs.

INS3 can help to Digitally Transform Your Food and Beverage Manufacturing Operations!

INS3 helps get you there, no matter where you are at on the journey!

Get Data From Machines

Connect to any machine, PLC, or other devices. Augment what you have store on premise or cloud. Gain visibility from any device, dashboard, scoreboard or mobile.

Modernize SCADA and More

We help protect your investment in existing SCADA and stored data by architecting a hybrid solution utilizing your existing infrastructure and incorporating new technology where appropriate to save money and enhance data access and longevity. Go thin, mobile, virtualize.

Get MES and KPIs

Gain insights into your plant by implementing MES functions like OEE, downtime, track and trace, ERP and more. We’ll get you connected and show you your process in a way that improves your results.

Apply Analytics

Start with the problems you are trying solve and look at the data available. Determine what is needed, cleanse the data and apply AI and ML techniques.

Ready to scale up your production?