Optimizing Ice Cream Production with AI-Driven Cost and Quality Control

An ice cream manufacturer faced challenges with raw material variability, especially milk fat content, leading to inconsistent quality and higher costs. INS3 implemented AI-driven least cost analysis and predictive quality monitoring to optimize processes.

The Challenge

Material Variability:

Milk fat differences impacted texture and flavor.

Cost Inefficiencies:

Overuse of costly ingredients due to manual adjustments.

Rework:

Inconsistent quality caused frequent rework.

The Solution

AI-Driven Optimization:

Automated least cost formulations based on real-time milk fat data.

Predictive Quality Monitoring:

AI provided live insights to maintain consistent texture and flavor.

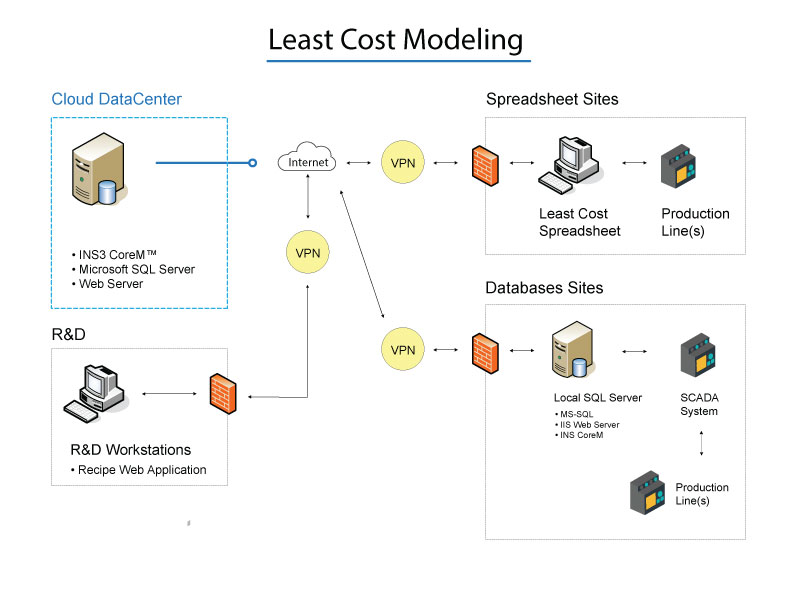

Integrated Systems:

Unified supplier and production data for seamless analysis.

The Results

- Cost Savings: Reduced ingredient costs by 18%.

- Quality Consistency: 30% reduction in deviations.

- Waste Reduction: 20% fewer rework cycles.

INS3’s AI solution optimized ingredient usage and improved product consistency, delivering significant cost savings and enhanced customer satisfaction.

INS3 Tip

Not sure where to start? Start by collecting the time and event series data. Analytics run best with a lot of correlated data and you never know the variable that will be the most important. Or if you’ve got questions, let us help.