Smart Manufacturing - MES Solutions, Manufacturing Data Analytics and SCADA

New, upgrade and migrate your existing systems to modernize and get to Industry 4.0. Discover the possibilities with real-time information and Manufacturing Execution System (MES). We are a system integrator that specializes in MES Solutions, SCADA, and IIoT Analytics. Proven and guaranteed manufacturing data solutions to improve productivity, quality, visibility, and overall equipment efficiency (OEE).

Smart Manufacturing - MES Solutions, Manufacturing Data Analytics and SCADA

New, upgrade and migrate your existing systems to modernize and get to Industry 4.0. Discover the possibilities with real-time information and Manufacturing Execution System (MES). We are a system integrator that specializes in MES Solutions, SCADA, and IIoT Analytics. Proven and guaranteed manufacturing data solutions to improve productivity, quality, visibility, and overall equipment efficiency (OEE).

Our Services

INS3: Your System Integrator for Manufacturing Data Analytics

We use our proven Discovery and Pathfinder processes to provide a phased path forward to improve efficiency, quality and reduce cost in your operations.

Innovate incrementally with our SCADA, MES and Industry 4.0 Solutions, as we convert raw data into actionable insights.

Industrial Data Infrastructure

Connect to your machines, collect data, store the data, and deliver information to the appropriate people, or systems in a secure way.

MES Solutions & Manufacturing Intelligence

Implement data driven systems that solve manufacturing issues like quality, efficiency, downtime, scheduling, consumption, connection to ERP, and more.

Data and SCADA Modernization

Upgrade or migrate SCADA systems, move to a modern architecture process monitoring and data analysis

Manufacturing Data Analytics

Gain a competitive edge by leveraging Big Data, IIOT, and Industrial Data Analytics for manufacturing. A clear path to results driven analytics.

How We Work

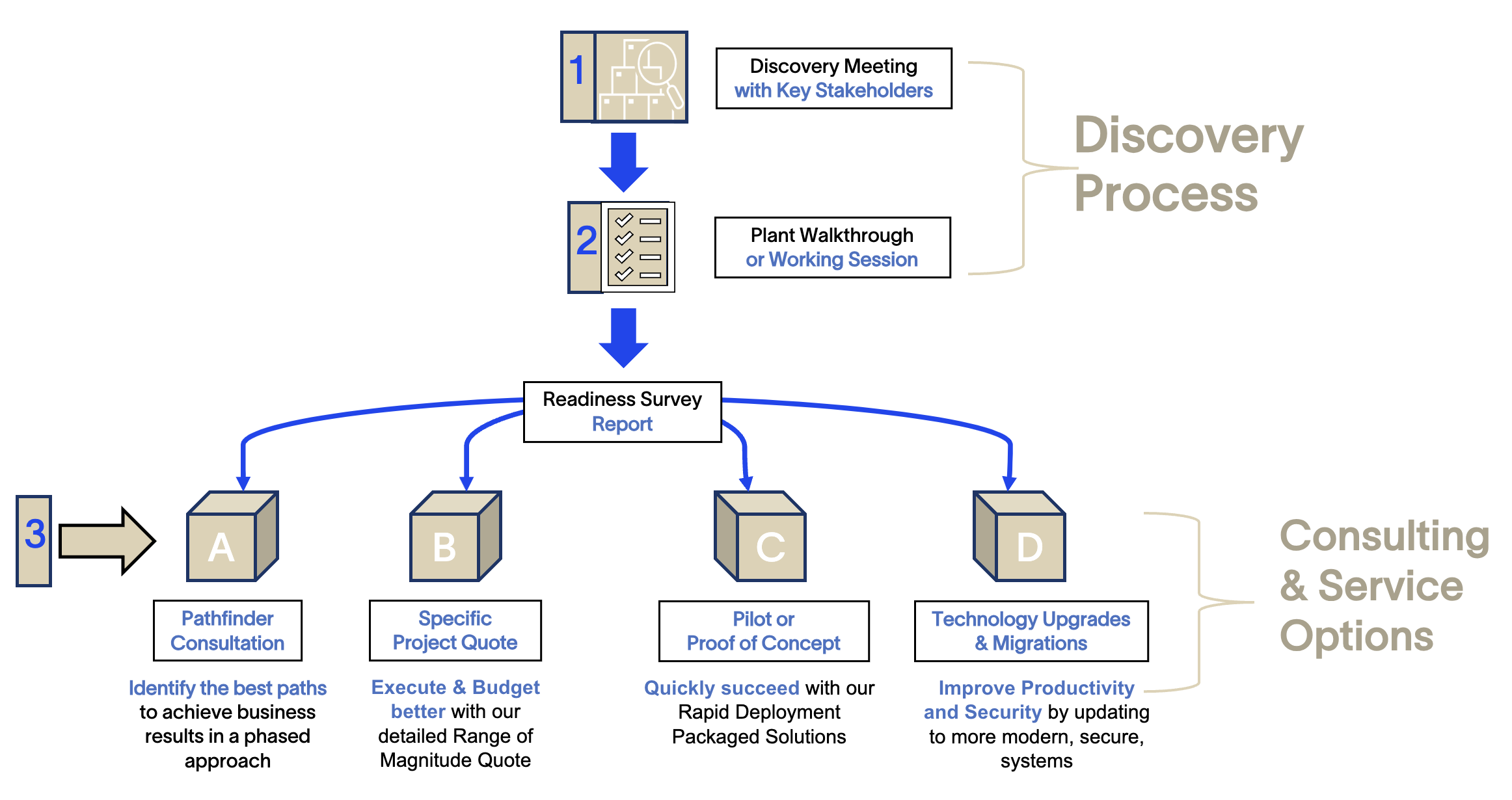

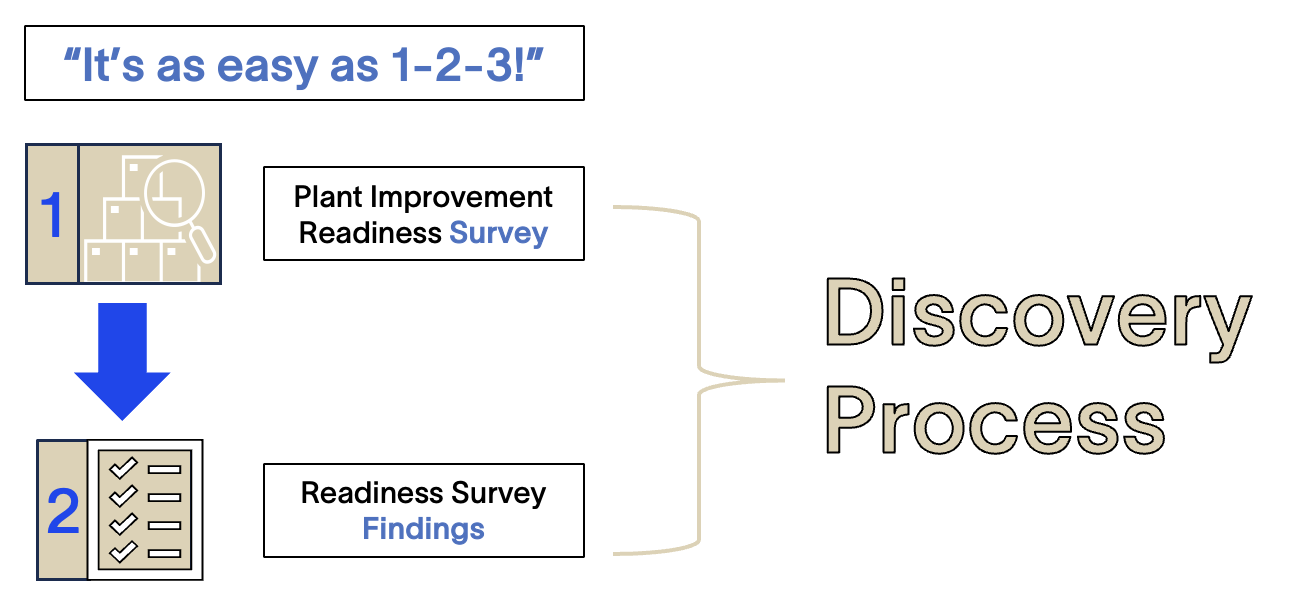

Accelerate ROI with our Proven Discovery Process

Our discovery process begins with aligning with key stakeholders where we delve into your business challenges and discuss potential solutions (MES Solutions, SCADA, Industrial Data Analytics or other tools).

Next, we schedule and complete a Plant Walkthrough and/or a Working Session, depending on your unique situation. The results of the Plant Walkthrough are summarized in a Discovery Report, and together we decide on the next steps.

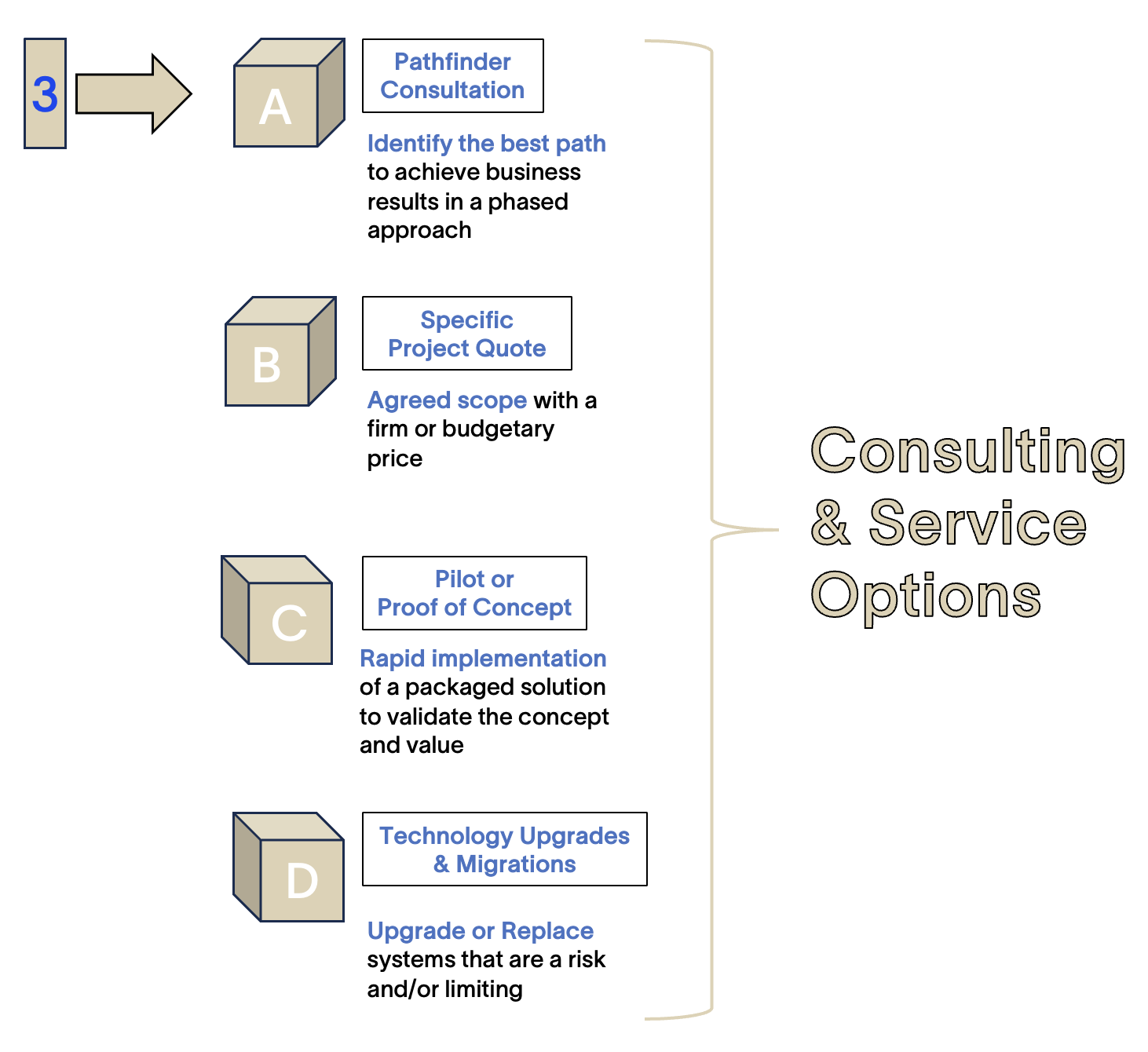

Typical next steps can include one or more of the following: a Range of Magnitude quote for a specific project or system upgrade OR a recommended pilot with one of our Rapid Deployment Solutions for quick proof of concept, OR a Pathfinder Consulting engagement for companies to further investigate project definition and justification The goal is to be clear on what needs to be done, timing, cost and expected results.

Our Customers

Join these Manufacturing Leaders

We are a dedicated System Integrator team of technology and manufacturing process experts committed to delivering significant business results for our customers!

System Integrator with 30+ years of Experience

INS3 enables smart manufacturing by bringing together people, process, technology and value-added solutions. In a world that demands better products and more sustainable processes, INS3 gives you the freedom to innovate through AI in manufacturing and lead the path towards digital transformation in manufacturing.

Boost Success, Minimize Costs

INS3's team of engineers uses practical and efficient technology to deliver optimized results. Our proven solutions lead to increased profitability and reduced operational expenses.

Enhance Operational Efficiencies

We understand your needs and goals to identify opportunities for improvement. With a focus on peak efficiency, we ensure every system in your plant operates at its best, positively impacting your bottom line.

Mitigate Risks

Automation and operational software are critical for consistent improvement, proactive measures, and issue mitigation. By automating functions, we ensure minimal downtime and peak efficiency for your production.

Optimize Capital Investment

From maintaining consistency and increasing efficiency to eliminating risks and maximizing security, our proven processes deliver fast returns on your investment. Our solutions cut operational costs, increase productivity, and boost profit margins.

Experience Counts

Our 2,337+ projects provided superior services to a wide range of clients, drawing on decades of combined experience in various industries. This allowed us to work with the many technologies and master the legacy software systems providing MES and industrial automation solutions that lead to SMART Manufacturing and Industry 4.0 benefits.

Our specialists have successfully completed projects, including new automation process software installations and existing system upgrades. Every plant is unique, with different goals and challenges. New or existing automation software, we’ll step in where needed. Our tailored solutions can help improve your operations and achieve your business’ objectives.

30+

Years of Transforming Businesses

2,337+

Successful Projects

813+

Satisfied Clients

Food & Beverage, CPG

Chemical & Industrial

Manufacturing & Discrete

Energy & Power

Pharmaceuticals & Life Sciences

Water & Wastewater

Food & Beverage, CPG

Chemical & Industrial

Manufacturing & Discrete

Energy and Power

Pharmaceuticals & Life Sciences

Water & Wastewater

Customer Stories

The AI Disconnect — Why Most Manufacturers Are Nowhere Near ‘Smart’

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

From Excel to MES — Why Mid-Market Manufacturers Can’t Afford to Stay Stuck in Spreadsheets (Even with Some Automation)

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Modernization Without Chaos — How to Upgrade Legacy Systems While Running at Full Speed

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Data Advantage: Why Manufacturing’s AI Success Depends on Quality Data Strategy

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Deloitte Manufacturing Industry Outlook 2025: Aligning with Results INS3 is Achieving with Manufacturers

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Truth About Generative AI in Manufacturing: Enhancement, Not Replacement

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Get Started with Smart Manufacturing.

We are ready to face any challenge. Send us your inquiry today.